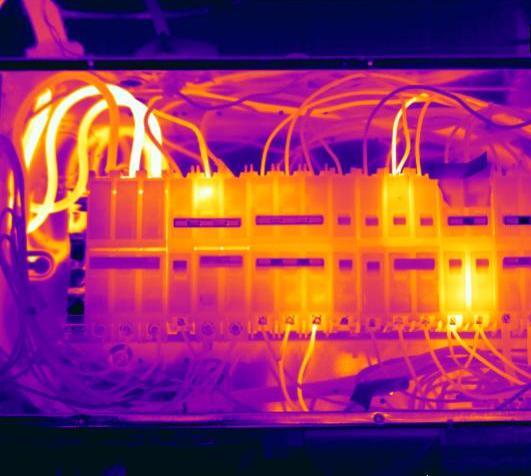

Infrared electrical inspections are essential for pinpointing hot spots resulting from connection and component defects. Utilizing infrared thermography, we identify areas with elevated heat due to increased resistance. This early detection allows us to address issues before they escalate, preventing damage to components, mitigating safety risks, and minimizing productivity loss.

Increased heating serves as an early warning sign of potential failure, making infrared the most effective diagnostic tool for detecting these hot connections in their initial stages of deterioration. It's the reason your insurance company may have requested an electrical infrared inspection—to proactively identify and prevent issues that could otherwise harm your personnel, equipment, and facility.

Increased heating serves as an early warning sign of potential failure, making infrared the most effective diagnostic tool for detecting these hot connections in their initial stages of deterioration. It's the reason your insurance company may have requested an electrical infrared inspection—to proactively identify and prevent issues that could otherwise harm your personnel, equipment, and facility.

|

Conditions detectable by an infrared inspection:

|

Benefits of infrared inspection:

|